Plasma Nitriding Theory(3): Characteristics of Ion Nitriding

- Doctor X

- Oct 16

- 4 min read

1、 Plasma nitriding theory

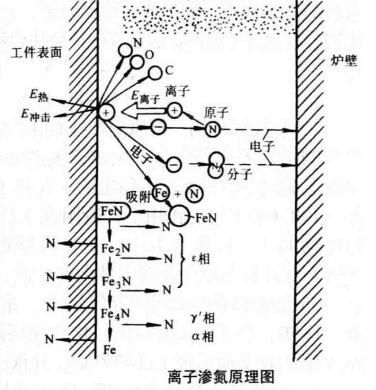

The theory of ion nitriding began to be applied in production practice in the 1960s, and it has been nearly forty years since then. Ion nitriding has become the most mature, popular, and vibrant process in ion heat treatment technology. With the advancement of process technology, the theory of ion nitriding is constantly being enriched and improved. However, there is still no theory that can explain all ion nitriding phenomena. Therefore, in this sense, the practical application of plasma heat treatment has far exceeded its theoretical framework. Under different experimental conditions, several ion nitriding theories have been proposed, including sputtering, nitrogen hydrogen molecule ionization, and neutral atom bombardment. Although these theories have certain limitations to varying degrees, it is undeniable that they all guide the research and practice of applied technologies to a certain extent. The following is only a brief introduction to sputtering theory. Sputtering theory is a classic theory that is widely accepted (or assumed) by many people. It was proposed by J. Kolbel in 1965, and its model is shown in Figure 3-1. This theory suggests that the nitriding layer is formed by cathodic sputtering. In the vacuum furnace, the workpiece is the cathode and the furnace body is the anode. After applying a high DC voltage, the rarefied gas ionizes and forms plasma. Positive ions such as N+, H+, NH3+are accelerated in the cathode depletion region and bombard the surface of the workpiece (cathode), consuming their kinetic energy:

① Convert into thermal energy to heat the workpiece.

② Generate secondary electron emission by emitting electrons.

③ Cathode sputtering.

High energy positive ion bombardment of the cathode causes atomic sputtering of C, N, O, Fe, and other atoms. Fe continuously atomizes with the active nitrogen near the cathode surface to synthesize the high nitrogen compound FeN (Fe becomes the carrier of active nitrogen). Due to backscattering, it is deposited on the cathode surface. Subsequently, under the action of ion bombardment and thermal activation, iron nitride decomposes (FeN → Fe2N → Fe3N → Fe4N) and transforms into low nitrogen compounds. Some of the nitrogen atoms decomposed diffuse into the steel, while others return to the plasma region. The main test basis of this model is to collect the quenched sputter deposits, and analyze that the nitrogen content in them is about 19.7%, so it is inferred that the theoretical content is 20.05% FeN.

2、 Characteristics of ion nitriding

(1) Compared with gas nitriding, ion nitriding has many advantages, mainly manifested in:

1. Plasma with fast infiltration rate not only has strong nitriding ability, but also can activate the surface of the workpiece, producing defects that accelerate absorption and diffusion. Therefore, ion nitriding can greatly shorten the nitriding time, especially in shallow nitriding. For example, when the depth of the nitriding layer is 0.3~0.5mm, the time for ion nitriding is only 1/3~1/5 of that for ordinary gas nitriding.

(2) The microstructure of the infiltration layer is easy to control, and a compound layer of more than 20 μm will appear on the surface of the brittle small gas nitriding workpiece, which is an uneven mixture layer composed of ε+γ' - phases, and the inner layer is the diffusion layer. Therefore, three-dimensional micro stresses are generated within the compound layer, and if a slight external force is applied in this stress direction, tiny cracks will form. This crack gradually expands and causes the entire compound layer to peel off. The compound layer of chromium and aluminum nitriding steel is very brittle, and it must be ground off before use after gas nitriding. Ion nitriding can be achieved by controlling the ratio of nitrogen to carbon content in the atmosphere, or the ratio of N2 to H2, to obtain a 5-30 μm thick brittle ε phase single-phase layer or a 0-8 μm thick γ - phase single-phase layer, as well as a more ductile nitriding layer without a compound layer but only a diffusion layer. This allows for direct installation and use without the need for grinding.

(3) The workpiece deformation is small due to the fast nitriding rate of ion nitriding, which greatly shortens the nitriding time. Additionally, ion nitriding can be carried out at lower temperatures (in fact, ion nitriding above 350 ℃ has a significant hardening effect), and the cathodic sputtering effect can compensate for some of the size expansion caused by nitriding. Vacuum heating and cooling can control the heating rate to make it uniform, so the deformation is smaller than gas nitriding.

(4) When energy-saving and gas saving ion nitriding, due to the use of glow discharge to heat the workpiece, the energy utilization rate is high (mainly concentrated on the workpiece), and compared with other external heating devices for nitriding methods, the power consumption is relatively low. In addition, due to the fast speed and short cycle of ion nitriding, the energy consumption is inevitably lower than that of ordinary gas nitriding. According to statistics, the energy consumption is only 40% to 70% of gas nitriding. Ion nitriding is carried out at a low pressure of 66.5-798Pa, and the pressure of ion nitriding is only less than one percent of that of ordinary gas nitriding, so the gas consumption is extremely low, only a few percent of gas nitriding.

(5) Non toxic, odorless, and pollution-free gas nitriding, as well as salt bath nitriding, all have pollution problems. Ion nitriding can use N2+H2 and decompose ammonia without pollution issues. Even if ammonia gas is used for ion nitriding, due to its low pressure and minimal usage, it will not cause pollution or explosion problems. In addition to the above advantages, ion nitriding also has the characteristics of superior layer properties (wear resistance, corrosion resistance, etc.) compared to gas nitriding, low equipment maintenance costs, long service life, and low labor intensity.

3、 Shortcomings of ion nitriding:

(1) Ion nitriding equipment is relatively complex, and one-time equipment investment is usually higher than gas nitriding.

(2) Advanced technological equipment requires a high level of quality from workers.

(3) Accurately measuring the temperature of the parts is difficult.

(4) The temperature field of ion nitriding is uneven, and it is difficult to achieve uniform and consistent temperature of each workpiece (especially mixed), which requires accumulating some experience.

Comments