Why Titanium Alloys Need Plasma Nitriding Treatment

- Doctor X

- Oct 6

- 3 min read

Introduction

Titanium alloys are among the most advanced engineering materials available today. Their combination of high strength, low density, and exceptional corrosion resistance makes them indispensable in aerospace, biomedical, and industrial applications. However, titanium has one major limitation: relatively poor wear resistance. This weakness often leads to premature failure in demanding environments. Plasma nitriding offers a reliable and efficient solution to enhance the surface performance of titanium alloys without compromising their core properties.

Challenges of Titanium Alloys

While titanium alloys excel in strength-to-weight ratio, they suffer from:

Low hardness: Pure titanium has a hardness of around 150–200 HV, making it prone to scratching and abrasive wear.

High friction coefficient: In sliding or rotating components, titanium tends to gall or seize.

Medical concerns: For implants, excessive wear can release titanium particles into the body, raising biocompatibility issues.

Aerospace and industrial limitations: In high-load or high-temperature conditions, titanium parts may degrade faster than expected.

These challenges highlight the need for advanced surface engineering techniques.

What is Plasma Nitriding?

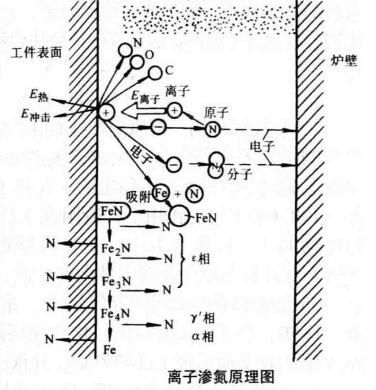

Plasma nitriding is a thermo-chemical surface treatment carried out in a vacuum chamber. A glow discharge plasma is generated, bombarding the titanium surface with nitrogen ions. These ions penetrate the surface and form a hard nitride layer.

Key characteristics:

Low temperature (450–750°C): Prevents distortion and preserves the core mechanical properties.

Strong bonding: Unlike coatings, the nitrided layer is metallurgically bonded, eliminating risks of peeling.

Customizable depth: Treatment duration and process parameters can be tuned for different applications.

Benefits of Plasma Nitriding for Titanium Alloys

Higher Surface HardnessThe surface hardness can increase from ~200 HV to over 1000 HV, drastically improving wear resistance.

Improved Tribological BehaviorReduced friction and minimized galling under sliding contact.

Enhanced Corrosion ResistanceThe nitrided layer offers additional protection, especially in marine or biomedical environments.

Extended Component LifespanReduced maintenance and longer service intervals, lowering the total cost of ownership.

Preserved Bulk PropertiesSince plasma nitriding is a diffusion-based treatment, the toughness and fatigue resistance of the core remain unchanged.

Applications of Plasma Nitrided Titanium

Aerospace: Turbine blades, structural fasteners, landing gear components.

Medical: Hip and knee implants, dental implants, surgical instruments.

Industrial: Pumps, valves, compressor parts, cutting tools.

Energy: Offshore drilling components, nuclear equipment, chemical processing parts.

These applications show how plasma nitriding enables titanium alloys to perform in harsher environments and under more demanding conditions.

Case Example

A titanium valve used in a chemical processing plant typically fails within a few months due to abrasive and corrosive wear. After plasma nitriding, the valve’s lifetime increased by over 300%, reducing downtime and replacement costs significantly. This kind of improvement illustrates why many industries now view plasma nitriding as an essential treatment for titanium components.

Conclusion

Plasma nitriding transforms titanium alloys into high-performance materials suitable for the toughest applications. By dramatically increasing hardness, reducing friction, and enhancing corrosion resistance, this treatment ensures that titanium parts last longer and perform more reliably.

At Doctor X, svetovanje, d.o.o., we specialize in cross-border plasma nitriding services for titanium and other advanced alloys. With strict confidentiality protocols, international logistics solutions, and industry expertise, we help clients in aerospace, medical, and industrial sectors achieve superior material performance.

Comments