Plasma nitriding theory (2):Volt-ampere characteristics of gas discharge

- Doctor X

- Oct 9

- 5 min read

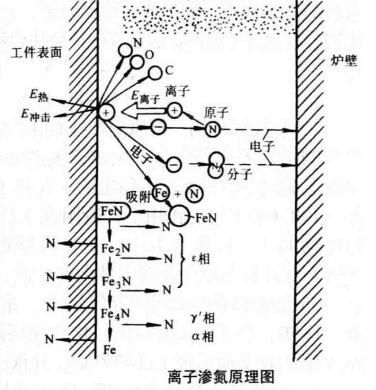

Plasma nitriding theory: Gases composed of neutral atoms and molecules are generally non-conductive. However, due to ionization by various naturally occurring radiation (cosmic rays, ultraviolet light, gamma rays from radioactive elements, etc.), trace amounts of primary charge (primary carriers) are generated. In the atmosphere near Earth's surface, their concentration is approximately 1000 ion pairs/cm³. Consequently, under a high-voltage DC electric field, electrons in the low-pressure (rare) gas are accelerated toward the anode, where they collide with gas atoms and molecules, continuously ionizing them and producing new electrons and ions—self-excited (or secondary) carriers. The positive ions generated in this process, accelerated by the electric field, bombard the cathode, causing secondary electron emission and sustaining the discharge process. Thus, the gas becomes conductive. As the discharge current increases, the discharge gradually intensifies, transitioning from a Townsend discharge to a glow discharge and then an arc discharge. These latter two types of discharges are so-called "self-sustaining" discharges, i.e., discharges that can be sustained without an external ionization source.

The device for measuring the relationship between voltage and current between two electrodes during gas discharge (see Figure 1) and the resulting volt-ampere characteristic curve are shown in Figure 2.

In Figure 1, A is the anode, B is the cathode, C is the discharge tube, V is the DC power supply, K is the switch, and R is the current limiting resistor.

1-glow discharge 2-normal discharge 3-abnormal discharge 4-arc discharge

Fig.2 is a gas discharge volt-ampere characteristic curve measured by the device shown in ig.1 . It can be seen that when the gas discharges between the anode and cathode, the relationship between the voltage and current between the two electrodes does not conform to Ohm's law.

As the power supply voltage is gradually increased across the vacuum container's electrodes, the interelectrode voltage is initially very low, preventing collisional ionization between electrons and the gas. Consequently, no visible current flows between the cathode and cathode, and the discharge is sustained only by an external power source. When the voltage reaches point C (Vs), the non-self-sustaining discharge transitions to a self-sustaining discharge sustained by secondary electron emission. A sudden surge of current flows between the electrodes, and a glow appears on part of the cathode surface. Further increasing the power supply voltage (or decreasing the current-limiting resistor) causes the interelectrode voltage to drop to the value at point E. Further increasing the power supply voltage or decreasing the current-limiting resistor increases the area of the cathode surface covered by the glow, increasing the current while maintaining the interelectrode voltage. By point F in the figure, the cathode surface is completely covered by the glow. Further increasing the power supply voltage (or decreasing the current-limiting resistor) increases the interelectrode voltage as the current increases, as shown in segments FG in the figure. Beyond point G, the current suddenly increases sharply, while the interelectrode voltage drops sharply. The glow extinguishes, and a strong arc discharge appears on the cathode surface.

The voltage at point C in Fig.2 is called the glow ignition voltage. The period before point C is called the non-self-sustaining discharge stage (i.e., it cannot be separated from the presence of a natural ionization source), and the period after point C is called the self-sustaining discharge stage (i.e., glow discharge). Segment OB is silent non-self-sustaining discharge, segment BC is non-self-sustaining dark discharge, segment CD is self-sustaining dark discharge, segment DE is the transition stage before self-sustaining normal glow discharge, and segment EF is the normal glow discharge region. The voltage in this region remains essentially constant, approaching the minimum value of the ignition voltage, which is approximately 400-500V in an ion nitriding furnace. Segment FG is called the abnormal glow discharge region, which is primarily used in ion nitriding furnace operation. In this region, the current can be adjusted by controlling the voltage, thereby controlling the heating temperature of the workpiece. The period after point G is called the arc discharge region. As can be seen from the figure, the current and voltage at point G are both very high. This type of arc discharge only occurs when the cathode surface is extremely pure. In ion nitriding furnaces, the transition to arc discharge often occurs at low voltage and current, and at very low temperatures. Arc discharge occurs between a small area on the cathode surface and the anode. A large number of positive ions bombard a small area of the cathode, causing it to melt and damage in a short period of time due to high temperatures. Therefore, care should be taken to avoid arc discharge in ion nitriding furnaces. The power supply control system should be able to automatically cut off the power supply to extinguish the arc when an arc occurs, then automatically ignite the glow and continue operation.

Normal Glow Discharge

Normal glow discharge is a stable, self-sustaining discharge, corresponding to the EF segment of the volt-ampere characteristic curve. During normal glow discharge, the glow light intensity distribution from cathode to anode is uneven. The entire discharge space from cathode to anode can be divided into eight regions: Aston dark region, cathode glow region, cathode dark region, negative glow region, Faraday dark region, positive column region, anode dark region, and anode glow region.

The sum of the Aston dark region, the cathode glow region, and the cathode dark region is called the cathode drop region. The sum of their widths is called the cathode drop region length dk. Adding the negative glow region width to dk yields the cathode discharge length. The cathode drop region is essential for maintaining glow discharge. During glow discharge, the voltage drop between the cathode and cathode electrodes is uneven. The voltage drops steeply in the cathode drop region, while the voltage drops in other regions are relatively stable.

During a normal glow discharge, with a constant gas type and cathode material, the cathode drop remains constant, equal to the minimum ignition voltage, regardless of gas pressure and inter-electrode distance. Specifically, in a normal glow discharge, with a constant gas type and cathode material, the cathode drop length dk is inversely proportional to the gas pressure P, meaning P·dk = a constant. For example, during a normal low-temperature glow discharge of ammonia, P·dk = 667 Pa/mm.

Abnormal Glow Discharge

During ion nitriding, the operating state should be adjusted to the abnormal glow discharge region of the volt-ampere characteristic curve, namely the FG segment in the figure. At this time, the discharge current density increases proportionally with the current, and the electric field becomes more distorted. The cathode drop and the cathode drop region are related to both gas pressure and current density, and the entire cathode is covered with glow. Compared with normal glow discharge, abnormal glow discharge has higher current and voltage, and also provides the necessary energy conditions for workpiece heating, gas phase reactions, and cathode sputtering. The color of the glow varies depending on the type of gas: hydrogen is light blue, nitrogen is purple-red, and ammonia is purple-blue.

Comments